Fume Extraction Systems

Based in Leicestershire, we serve clients throughout the Midlands, including Leicester, Birmingham, Nottingham, Coventry, and beyond.

Fume Extraction Systems

Based in Leicestershire, we serve clients throughout the Midlands, including Leicester, Birmingham, Nottingham, Coventry, and beyond.

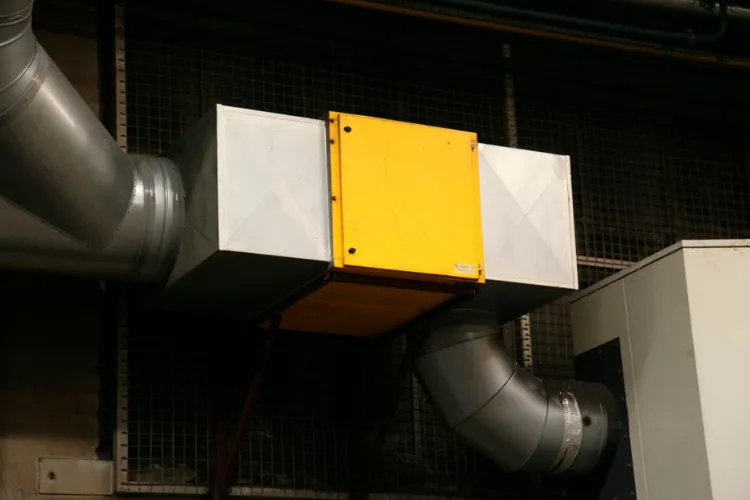

Fume Extraction Systems – Supply & Installation in the Midlands

At Workplace Safety Products & Services, we specialise in supplying and installing fume extraction systems across the Midlands, helping businesses maintain safer, compliant, and more productive workplaces.

Why Fume Extraction Is Essential: Fume extraction is critical for removing hazardous airborne contaminants such as welding fumes, soldering smoke, chemical vapours, and other industrial emissions. Without proper extraction, these pollutants can pose serious long-term health risks to employees and reduce workplace productivity.

Our Expertise in Workplace Fume Control:Our expert team designs and installs fume extraction solutions that capture harmful particles directly at the source. This targeted approach improves air quality, protects your workforce, and ensures compliance with UK HSE workplace safety regulations.

Workplace Fume Extraction

At Workplace Safety Products & Services, we specialise in supplying and installing fume extraction systems across the Midlands, helping businesses create safer, compliant, and more productive workplaces.

Fume extraction is essential for removing hazardous airborne contaminants such as welding fumes, soldering smoke, chemical vapours, and other industrial emissions.

Our expert team designs workplace fume extraction solutions that capture harmful particles at the source, improving air quality and protecting your workforce from long-term health risks.

As Midlands-based fume extraction specialists, we provide tailored systems for manufacturing, engineering, and industrial environments, ensuring full compliance with UK HSE regulations.

Whether you need a single fume extractor or a centralised extraction system, we deliver reliable, cost-effective solutions with ongoing support to keep your workplace safe.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

FUME / DUST EXTRACTOR ARMS

Our versatile extraction arm is the ideal solution for small to medium-sized workplaces, offering unmatched flexibility for capturing fumes, gases, and oil mist directly at the source.

Designed with an external, easy-to-adjust elbow joint and a spring-assisted double joint, it allows smooth one-motion manoeuvring. The hood can be angled up to 110° in any direction, so you can position it exactly where it’s needed for maximum efficiency.

Constructed from smooth aluminium tubing, both the inner and outer arms are lightweight yet robust, delivering improved airflow, reduced noise, and excellent durability—even at high air volumes.

For larger work areas or applications without a fixed workstation, the Traversing KUA-Arm on an Extension Rail provides extended reach and mobility.

FUME / DUST

EXTRACTOR ARMS

Our versatile extraction arm is the ideal solution for small to medium-sized workplaces, offering unmatched flexibility for capturing fumes, gases, and oil mist directly at the source.

Designed with an external, easy-to-adjust elbow joint and a spring-assisted double joint, it allows smooth one-motion manoeuvring. The hood can be angled up to 110° in any direction, so you can position it exactly where it’s needed for maximum efficiency.

Constructed from smooth aluminium tubing, both the inner and outer arms are lightweight yet robust, delivering improved airflow, reduced noise, and excellent durability—even at high air volumes.

For larger work areas or applications without a fixed workstation, the Traversing KUA-Arm on an Extension Rail provides extended reach and mobility.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

OIL MIST CENTRAL SYSTEM

The new One for All mechanical coolant filter from Workplace Safety Products & Services is the ideal choice for businesses across the Midlands looking for a versatile, long-lasting coolant filtration system.

Designed to adapt to all machine tool processes, this single filter is fully reconfigurable to handle any type of coolant. As your workshop needs grow, it’s easy to expand—just add another module.

Perfect for manufacturers, engineers, and machining specialists, our coolant filters improve efficiency, reduce downtime, and keep your operations compliant with workplace safety standards.

Features and benefits include:

Limit exposure to hazardous coolant and fumes

Eliminating high cost for cleaning and ventilation

Improves employee moral with better working environment

No slippery floors – workers safety is paramount

Protection of sensitive high-tech equipment

Limitation of downtime on machinery

OIL MIST CENTRAL SYSTEM

The new One for All mechanical coolant filter from Workplace Safety Products & Services is the ideal choice for businesses across the Midlands looking for a versatile, long-lasting coolant filtration system.

Designed to adapt to all machine tool processes, this single filter is fully reconfigurable to handle any type of coolant. As your workshop needs grow, it’s easy to expand—just add another module.

Perfect for manufacturers, engineers, and machining specialists, our coolant filters improve efficiency, reduce downtime, and keep your operations compliant with workplace safety standards.

Features and benefits include:

Limit exposure to hazardous coolant and fumes

Eliminating high cost for cleaning and ventilation

Improves employee moral with better working environment

No slippery floors – workers safety is paramount

Protection of sensitive high-tech equipment

Limitation of downtime on machinery

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

OIL MIST EXTRACTION

Our Oil Mist Extraction system effectively removes coolant mist and smoke directly from your machine tools, making it the ideal solution for both single and multiple machine tool applications.

By capturing hazardous coolant fumes at the source, it dramatically reduces health risks and keeps harmful particles out of your employees’ breathing zones.

With global employee exposure limits for machining coolants becoming increasingly strict, compliance is essential.

Oil Mist Extraction systems help you meet these safety standards while improving air quality, protecting worker health, and creating a more comfortable, productive working environment.

Features and benefits include:

Filtering efficiency of the Oil Mist Extraction maximises the return of coolant back to your process, thus saving money by not having to replace lost coolant that is escaping from your machinery.

Energy consumption is 25-30% less per year than other competitive brands. This then guarantees a return on your investment in less than one year.

Workers safety is improved by reducing coolant from spreading throughout the workplace, thus eliminating slippery floors.

Operation costs will be lowered by not allowing coolant clouds to reduce the efficiency of your heating, lighting or cooling systems. Installation cost is lowered by direct mounting the Oil Mist Extraction to the machine tool, thus eliminating the need for costly duct work and complicated electrical connections.

OIL MIST EXTRACTION

Our Oil Mist Extraction system effectively removes coolant mist and smoke directly from your machine tools, making it the ideal solution for both single and multiple machine tool applications.

By capturing hazardous coolant fumes at the source, it dramatically reduces health risks and keeps harmful particles out of your employees’ breathing zones.

With global employee exposure limits for machining coolants becoming increasingly strict, compliance is essential.

Oil Mist Extraction systems help you meet these safety standards while improving air quality, protecting worker health, and creating a more comfortable, productive working environment.

Features and benefits include:

Filtering efficiency of the Oil Mist Extraction maximises the return of coolant back to your process, thus saving money by not having to replace lost coolant that is escaping from your machinery.

Energy consumption is 25-30% less per year than other competitive brands. This then guarantees a return on your investment in less than one year.

Workers safety is improved by reducing coolant from spreading throughout the workplace, thus eliminating slippery floors.

Operation costs will be lowered by not allowing coolant clouds to reduce the efficiency of your heating, lighting or cooling systems. Installation cost is lowered by direct mounting the Oil Mist Extraction to the machine tool, thus eliminating the need for costly duct work and complicated electrical connections.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

Service Contracts & LEV P601 Accredited Testing

Stay Compliant. Stay Protected. Stay Operational. Keeping your extraction and ventilation systems in top condition isn’t just good practice — it’s a legal requirement.

Our service contracts and LEV testing services ensure your workplace remains safe, compliant, and fully operational all year round.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

COMPANY INFO

CUSTOMER INFO

2025 Workplace Safety Management & Products | Web Design by Tubby Creative